technical paramete

technical parameteMaximum wind resistance: 52m/s

Maximum snow resistance: 1.5KN/m2

Span range: 0.6-3.2m

System installation angle deviation: ± 2 °

Design standard: AS/NZS1170 ASCE 7-05 DIN1044

GB50797-2012 GB 50017-2003 Steel structure design

specifications, etc.

specifications, etc.Performance parameter

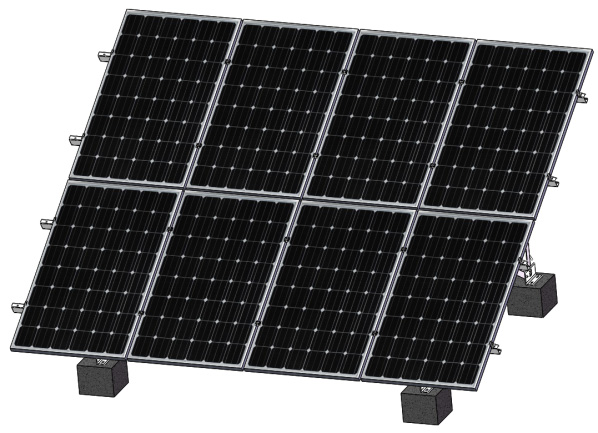

Installation site: flat roof or level ground

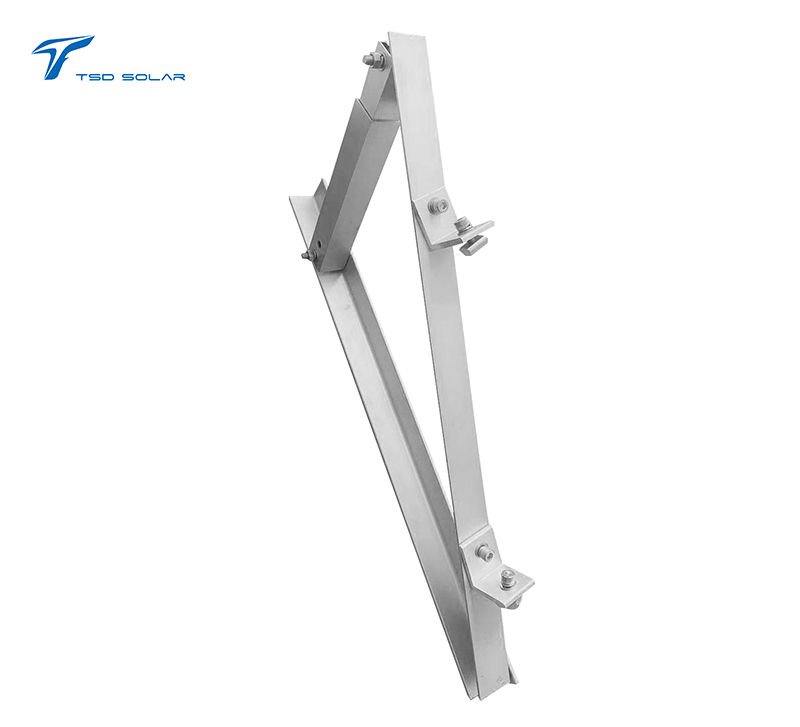

Body material: Q235B

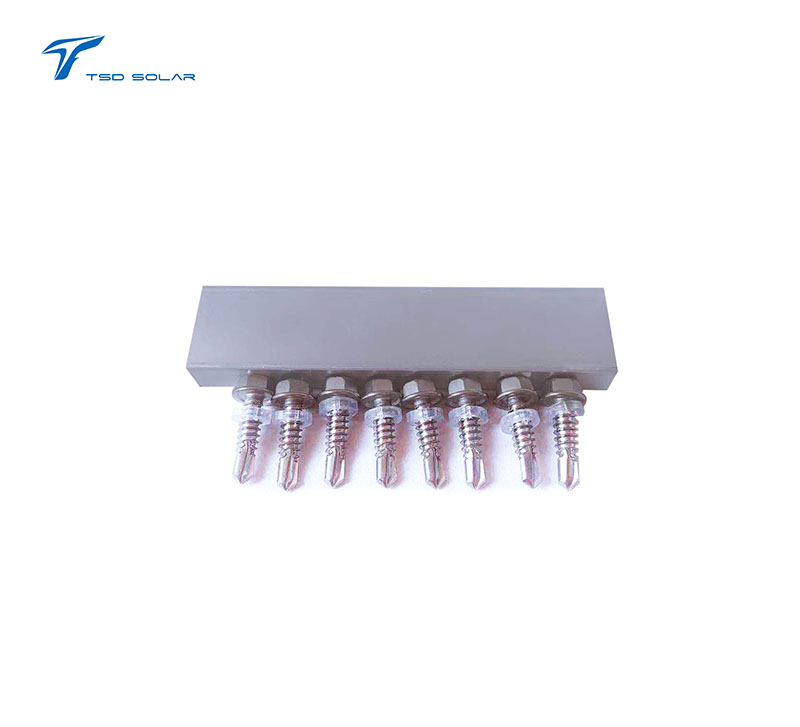

Fastener material: SUS304 or hot-dip galvanized steel

Applicable components: framed or frameless

Applicable arrangement: vertical or horizontal

Warranty period: 10 years

支架系统零部件

产品特点

- Strong compatibility

The carbon steel bracket system can meet the installation requirements of different specifications of PV modules. At the same time, it is compatible with the different arrangement of components.

The carbon steel bracket system can meet the installation requirements of different specifications of PV modules. At the same time, it is compatible with the different arrangement of components. - Safe and reliable

The carbon steel bracket system mainly uses hot-dip galvanized carbon steel material to effectively prevent corrosion and oxidation. The overall structure of the bracket is stable, wind-resistant, snow-resistant, and shock-resistant, and has safe and reliable characteristics.

The carbon steel bracket system mainly uses hot-dip galvanized carbon steel material to effectively prevent corrosion and oxidation. The overall structure of the bracket is stable, wind-resistant, snow-resistant, and shock-resistant, and has safe and reliable characteristics. - Low price

The carbon steel bracket main body material is made of hot-dip galvanized carbon steel, and the price is much better than the traditional aluminum alloy.

The carbon steel bracket main body material is made of hot-dip galvanized carbon steel, and the price is much better than the traditional aluminum alloy.

安装说明

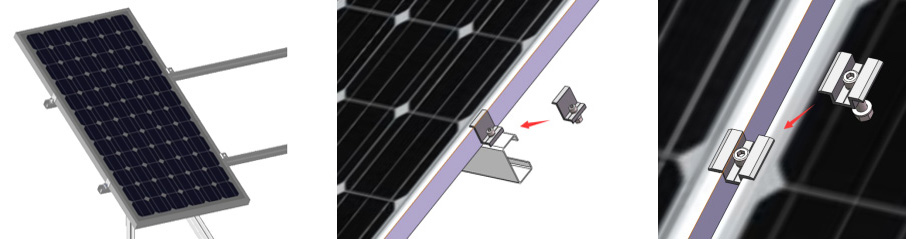

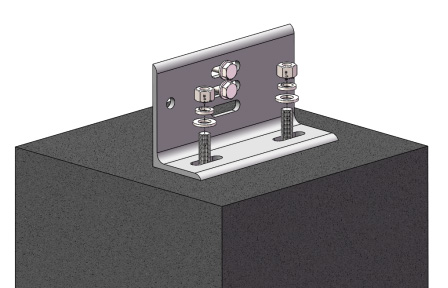

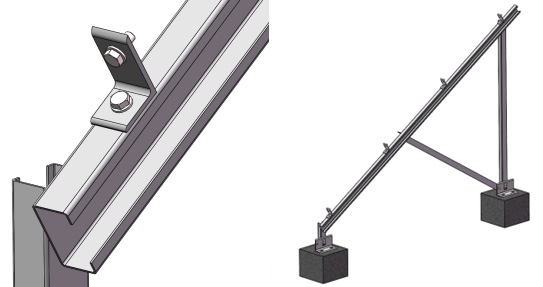

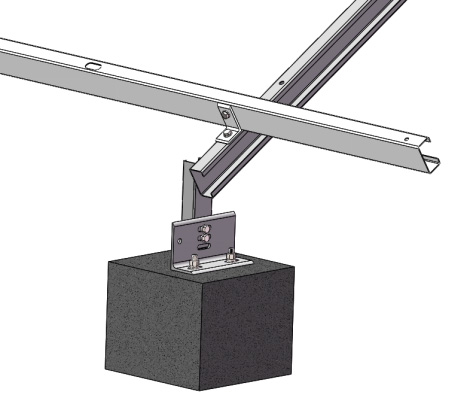

step1、Installation of carbon steel bracket

Fix the base on the cement foundation with the bolts embedded. As shown in Figure 1 (left); the pre-assembled bracket is unfolded and mounted to the base. As shown in Figure 2 (right).

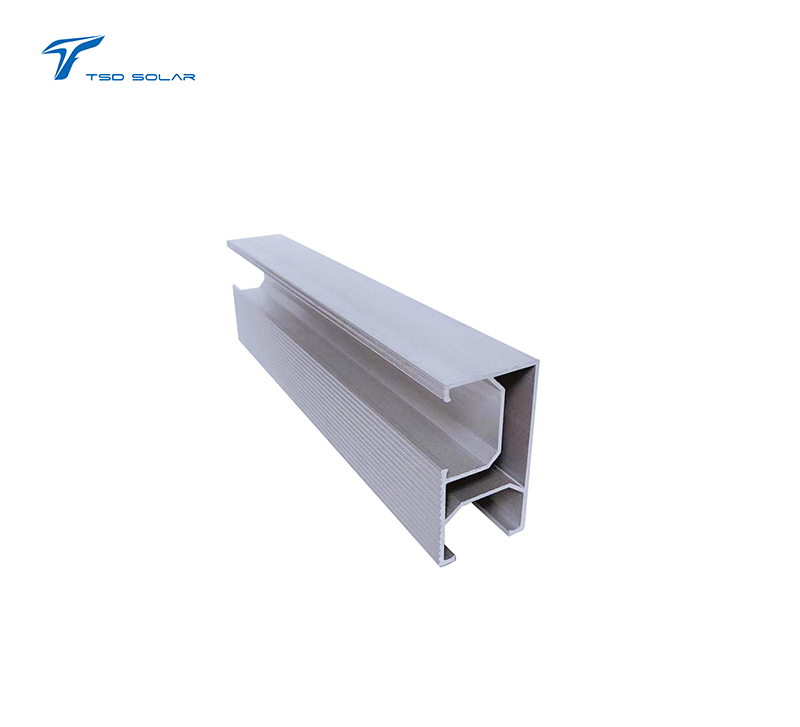

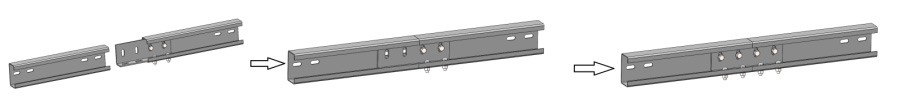

step2、Installation of purlins

Install the stern plate on the carbon steel bracket before installing the rafter as shown in Figure 3 (left), Figure 4 (middle); place the rafter on the bracket (the side of the opening is facing up) and fix it in the chin rest The board is shown in Figure 5 (right).

If the length of the stringer is not enough, it is possible to connect the plurality of stringers into one piece with a stringer connection. As shown 6

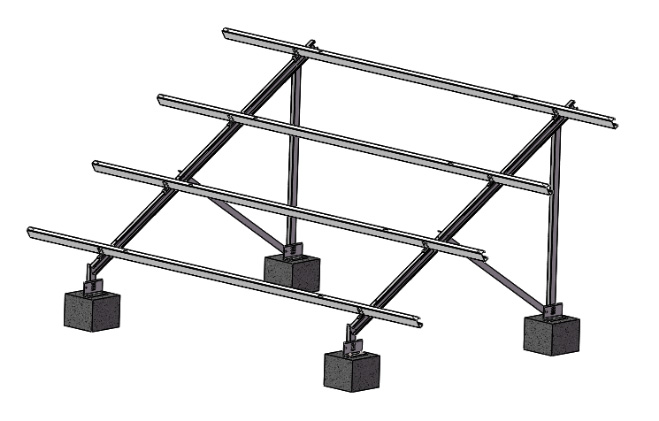

Install the ampule effect diagram, as shown 7

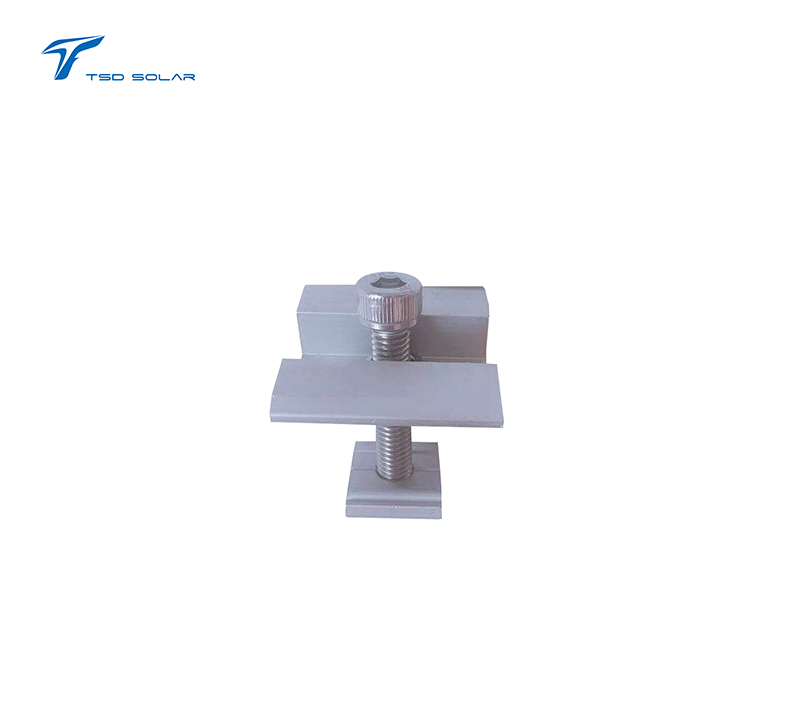

step3、Installation component

The components are tiled on the rails and the solar panels are installed in a designed position, secured by side clamp assemblies and medium pressure block assemblies. As shown below